// Virtual Drivetrain

From Vehicle Concept to Development

Cost-Reducing Simulations and Models

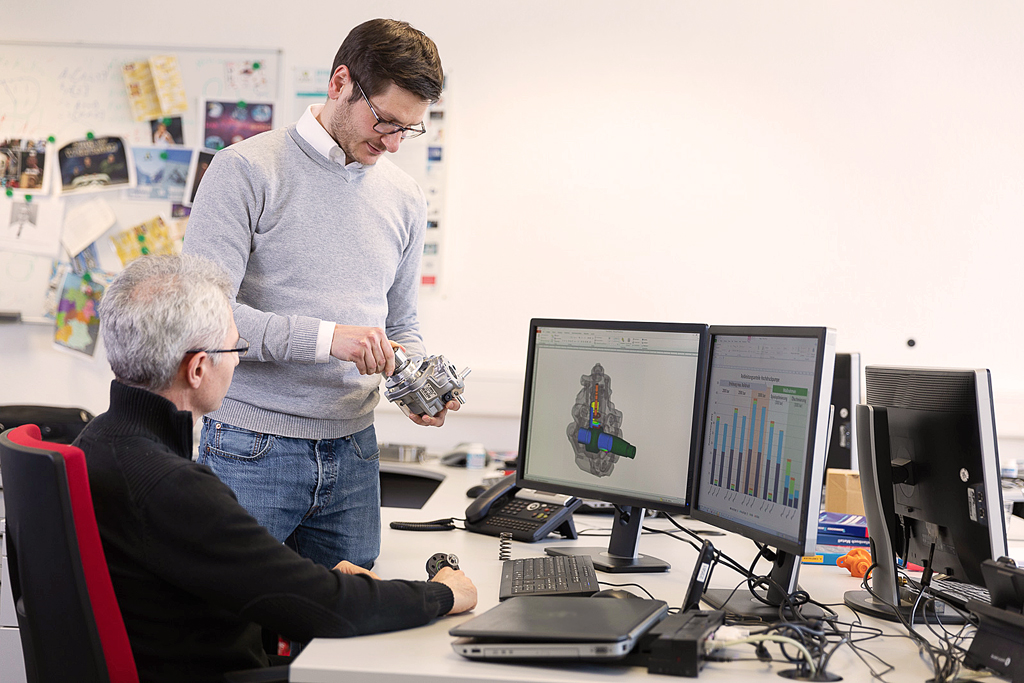

APL uses simulations and models at every stage of the product development process and life cycle. This not only reduces development costs, but also opens up new possibilities for supporting individual subtasks or accompanying the entire development process. Physical, hybrid and empirical models are used during this process.

Would you like to learn more about our competencies in virtual drivetrain development? Then click here for an excerpt from our portfolio.

Disciplines of Virtual Drivetrain Engineering

CAD

Complex 3D models are created with the latest CAD design tools. From new design concepts on a white sheet of paper to modification and adaptation services and reverse engineering of existing hardware, we design your and our ideas.

Structural Mechanics of Individual Components and Assembly Units

APL covers all common fields of structural mechanics such as strength and stiffness analysis of single components as well as drive assemblies of all kinds. Intelligent topography optimisation for weight reduction as well as simulations of NVH behaviour complete our portfolio.

Thermomechanics of Components

Thermomechanical calculations provide valuable information on the expansion and distortion behaviour of drive components in operation. In particular, the focus lies on thermally highly stressed components such as crankcases and exhaust systems, but increasingly also on cooling systems (for example in traction batteries of electric vehicles or fuel cell-based systems).

Dynamic Simulation

Tribology — Friction and Abrasion

Fluid Mechanics

Wherever liquids flow, CFD calculation becomes part of the equation. Issues such as gas exchange, carburetion, uniform flow distribution, combustion and exhaust gas aftertreatment are dealt with, as well as the thermal management of traction batteries and fuel cell-based systems – including cavitation-critical areas on components around which liquids flow. Depending on the operation purpose, we use 2D or 3D models as well as single-phase or multi-phase simulation approaches.

Electromagnetics and Electronics

Electrochemistry

Further optimization of fuel cell drives requires a fundamental understanding of the electrochemical processes inside a fuel cell. Many years of experience gathered by specialists working at APL allow for a comprehensive characterization of functional and loss mechanisms that occur. Combining the latest simulation and diagnostic tools we daily generate value for our customers on the path to a durable, highly efficient and at the same time inexpensive, emission free drive system.

Multiphysics

System Simulation

APL uses 0D and 1D approaches to represent the various subcomponents on a system basis. Examples are oil, cooling, battery and injection systems on subsystem level or complete vehicle models for internal combustion, hybrid, fuel cell and electric drives.

Real-Time Simulations

Systematic Variation and Optimisation

// Locations

Headquarters Landau

APL Automobil-Prüftechnik

Landau GmbH

Am Hölzel 11

76829 Landau

// Wolfsburg

APL Automobil-Prüftechnik

Landau GmbH

Gustav-Hertz-Straße 10

38448 Wolfsburg

// Bietigheim-Bissingen

APL Automobil-Prüftechnik

Landau GmbH

Robert-Bosch-Straße 12

74321 Bietigheim-Bissingen

// APL Group

@2022 APL Automobil-Prüftechnik Landau GmbH | Imprint | Privacy policy