// Electrified Drive Systems

The Future of Mobility Starts Now!

Electrifying drive systems achieves two major goals: compliance with current emission legislation by minimizing CO2 release and a simultaneous increase in driving comfort. APL has created a complex chain of methods to develop operating strategies and components for energy-efficient, emission-optimised real driving.

Development of Electrified-Drive Concepts

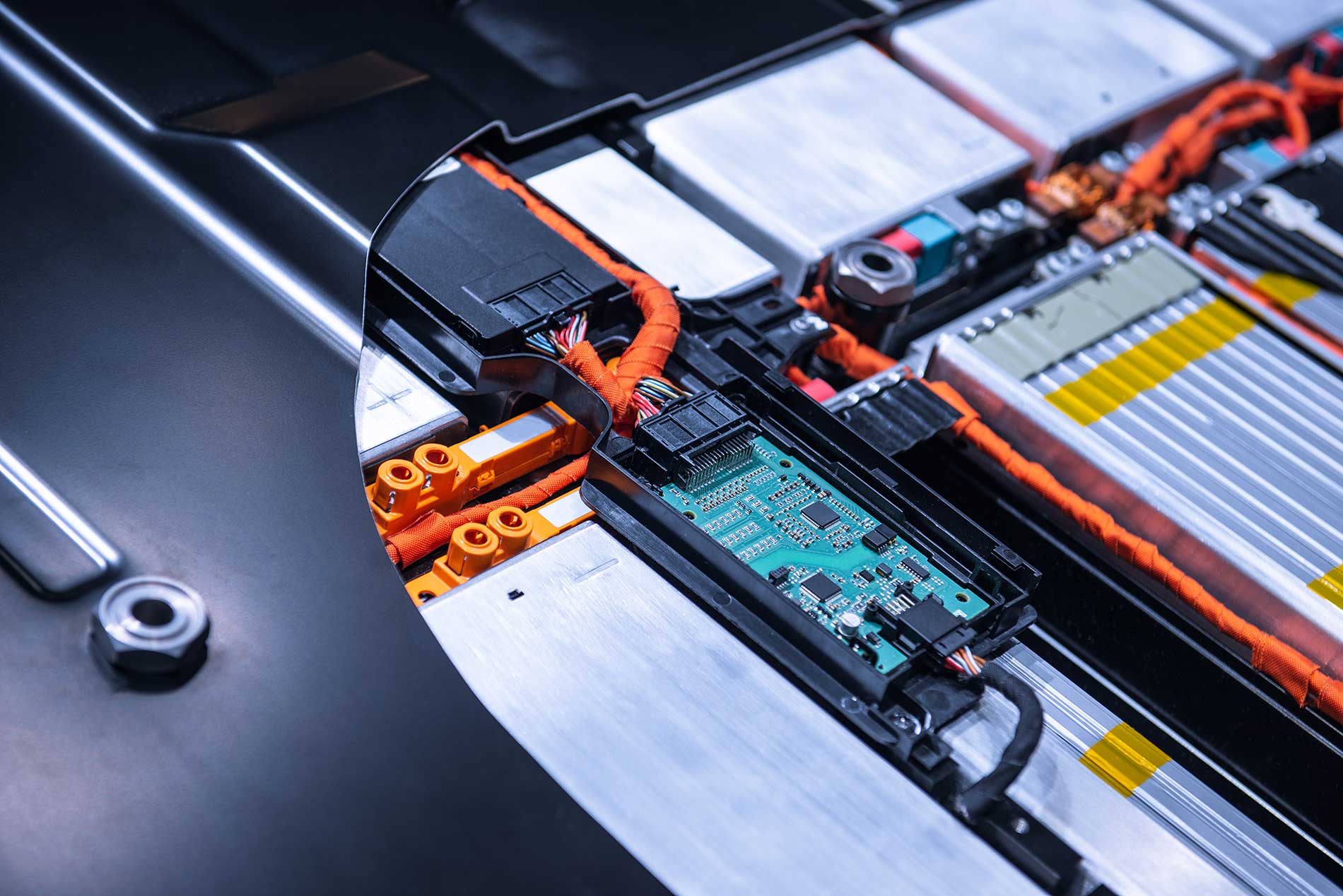

Together with its customers, APL is developing electrified drives for hybrid, fuel cell and battery-electric vehicles.

The focus is on development of system components, in addition to the overall drive system and software development & calibration.

Development of System Components

Battery Development Through Test and Simulation

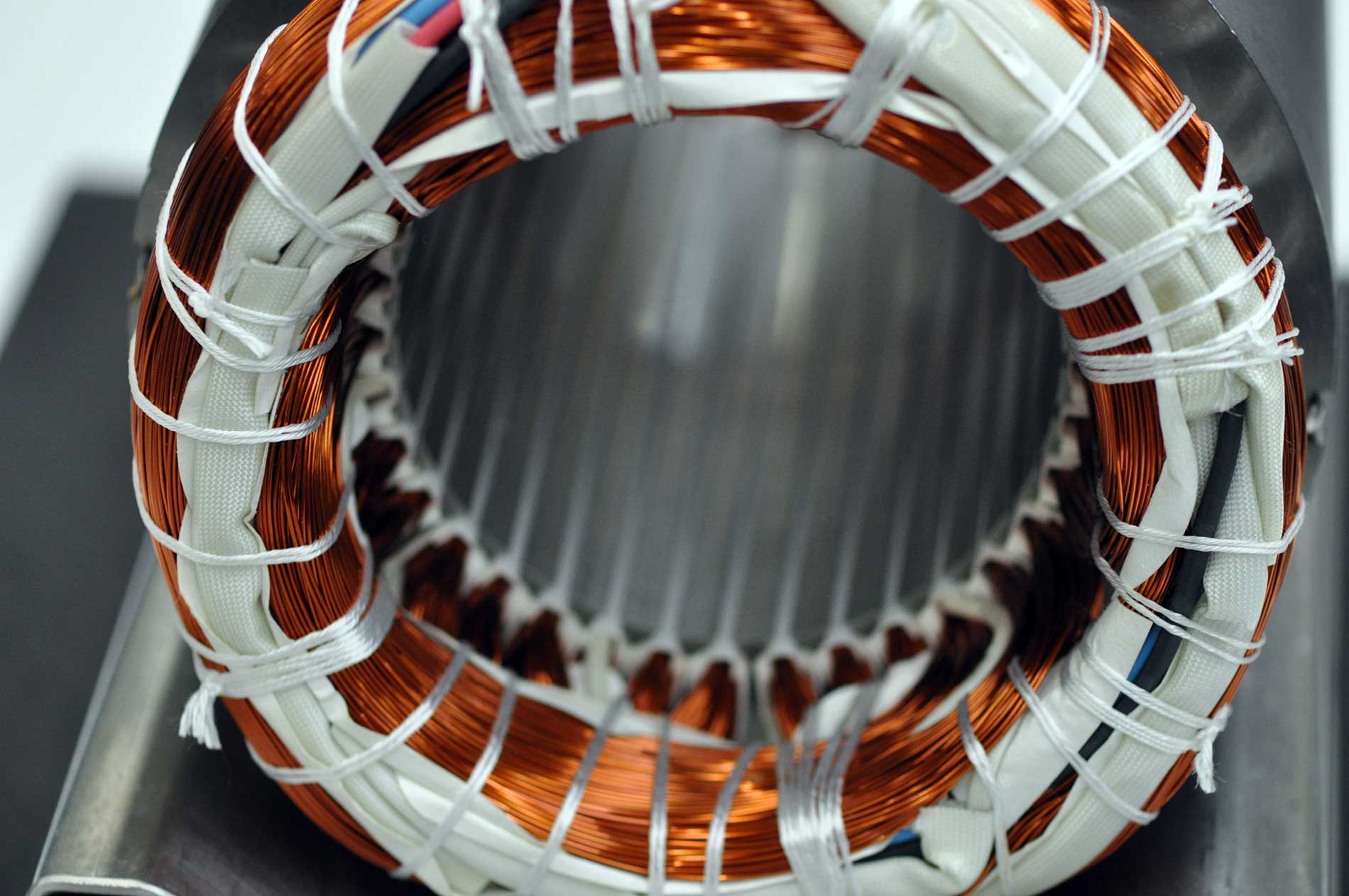

Electric Motor Development

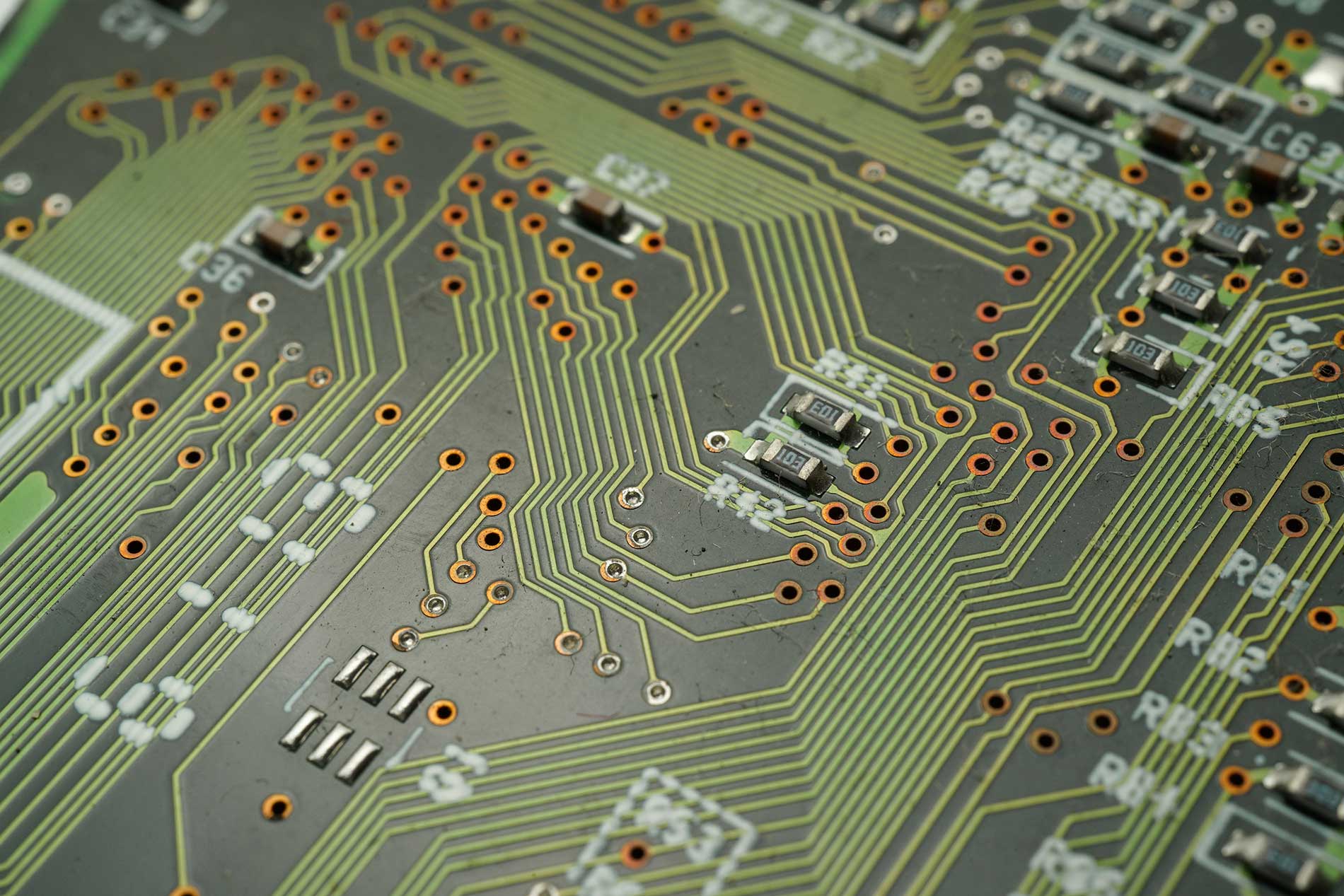

Basic Data Input and Functional Development

Using simulation models in a Matlab/Simulink environment and application tools such as INCA Flow or AVL Cameo, data for basic functions, or more complex functions such as the rotor temperature model, can be input based on models and (partially) automated. High demands with respect to precise torque control and reproducible mapping of temperature behaviour can be met on APL test benches.

Benchmark

Further Informationen

Article: Requirements for Operating Materials Applied in Hybrid Powertrains

März 2020

Related Topics:

Testing of Electrified Drives

Development of fuel cell drive

Chemical and Physical Laboratory

// Locations

Headquarters Landau

APL Automobil-Prüftechnik

Landau GmbH

Am Hölzel 11

76829 Landau

// Wolfsburg

APL Automobil-Prüftechnik

Landau GmbH

Gustav-Hertz-Straße 10

38448 Wolfsburg

// Bietigheim-Bissingen

APL Automobil-Prüftechnik

Landau GmbH

Robert-Bosch-Straße 12

74321 Bietigheim-Bissingen

// APL Group

@2022 APL Automobil-Prüftechnik Landau GmbH | Imprint | Privacy policy